The bending of metal pipes, profiles and tubular products is a cold forming process in which the straight pipe is bent. This article explains the cross-sectional deformation in the bent area of the tube that results from the cold bending of tubes.

It is important to make it clear from the outset that in the bent part of the pipe, the cross-section, deformation always occurs due to bending. In addition, the deformation of the bent pipe cross-section increases as the bending radius decreases, i.e. it is inversely proportional.

This means that for a given cross-section (e.g. pipe Ø50×2), the smaller the bending radius, the greater the deformation of the pipe cross-section in the bending area.

Do you know the difference between tube bending and tube rolling? Find out more in this article.

Deformation of bent round, square and rectangular pipes

To talk specifically about pipe deformation, it is first necessary to explain the different designations for the deformation of the material in the bending zone. A distinction must be made here as to whether it is a round pipe or a square/rectangular pipe.

Deformation of bent round tubes: Ovalization

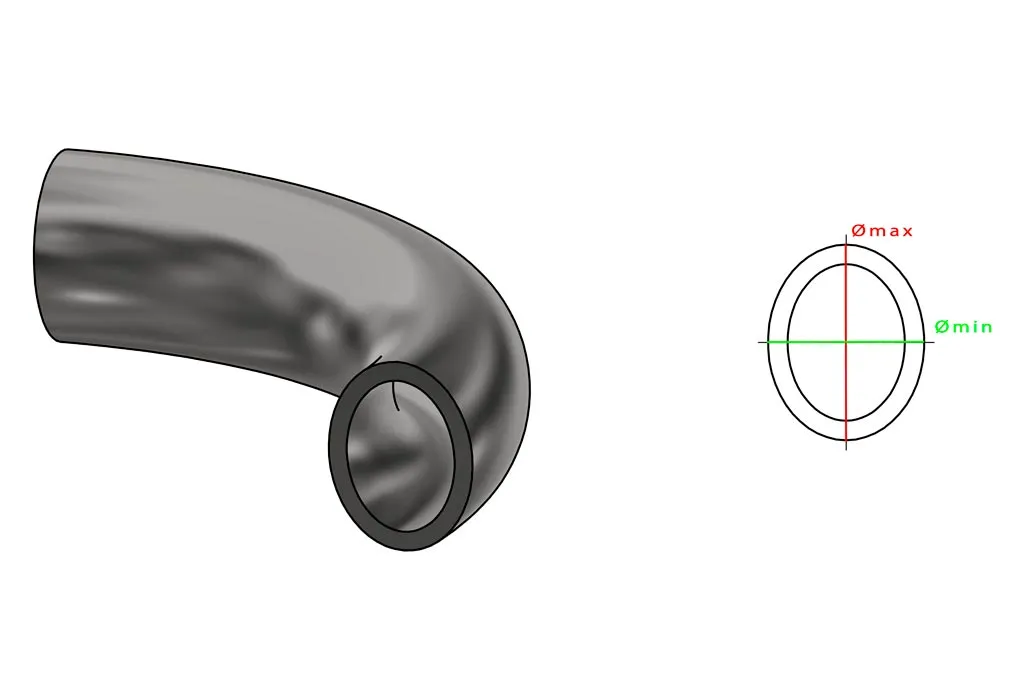

The deformation of the bent round pipe is referred to as ovalization and represents the maximum permissible deviation from the circular shape of the original pipe diameter.

Both when bending pipes and when rolling pipes the pipe tends to ovalize symmetrically. The ovalization also leads to a change in the diameter of the tube, as shown in the figure below.

How is the deformation of a bent round tube calculated?

The value of ovality, which is generally measured as a percentage (%), is calculated by comparing the maximum diameter (Ø max) with the minimum diameter (Ø min) after the tube has been processed, i.e. after bending and rolling.

However, there are industries, such as power plants, where ovality is such an important factor that it is regulated by specific standards (e.g. UNI EN 12952-5-2022).

Deformation of bent square and rectangular tubes

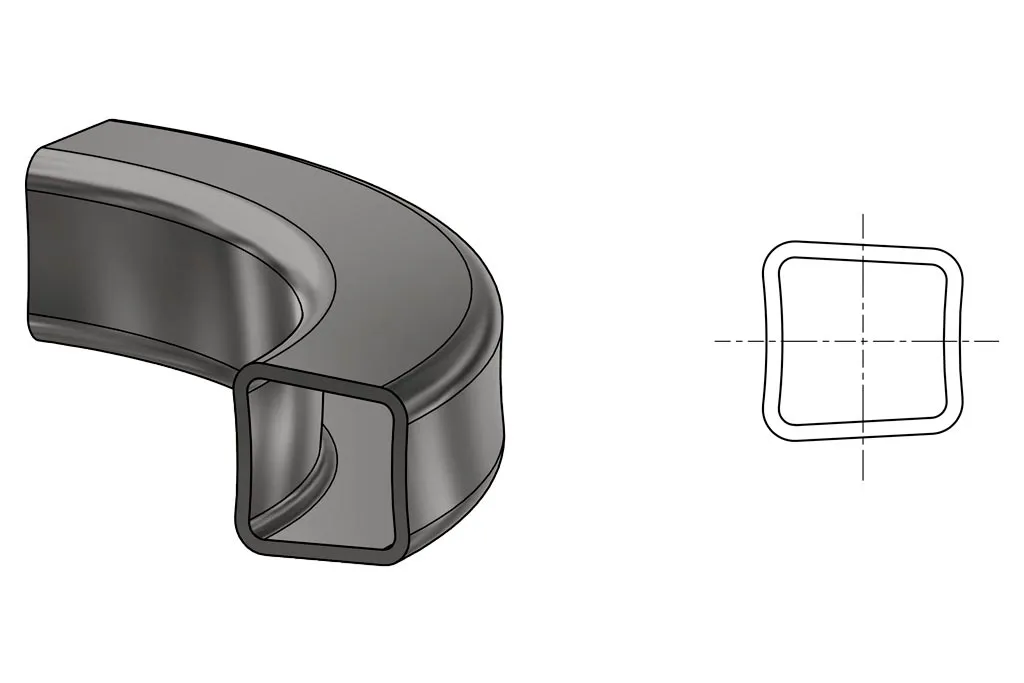

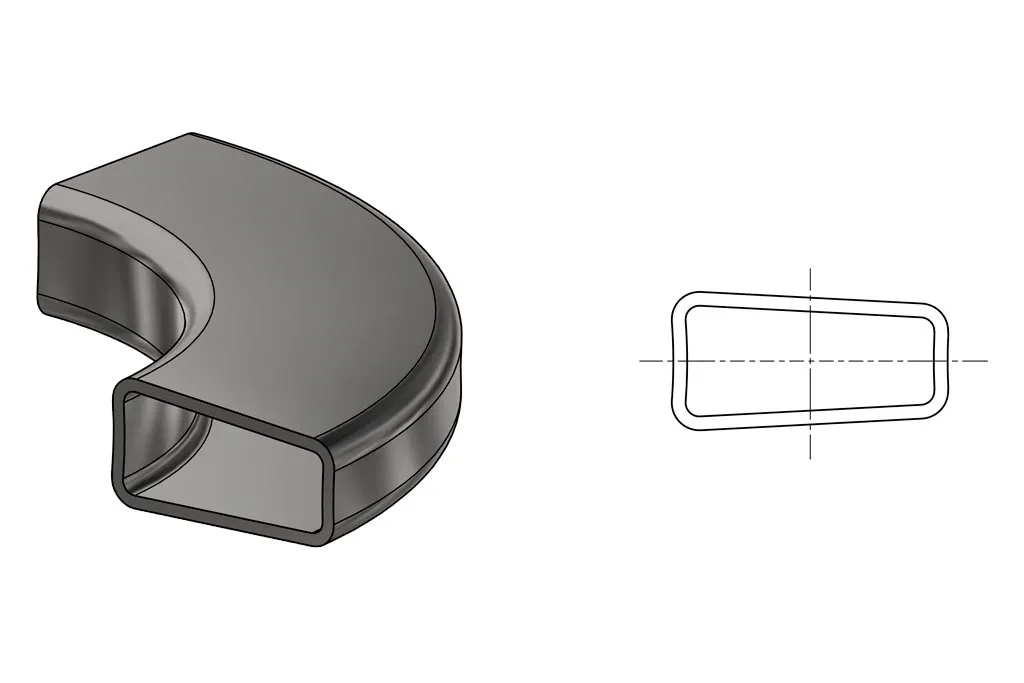

The bending deformation also occurs with square and rectangular pipe cross-sections.

As can be seen in the figure below, the bent part of the profile has a trapezoidal shape as a result of the deformation. In contrast to ovalization, this deformation is not symmetrical and exhibits convexity inside and outside the tube bend.

How do you calculate the deformation of a bent square or rectangular tube?

The deformation of square/rectangular tubes is calculated in mm by measuring both sides of the bent section and comparing them with the measurements taken before the tube was machined.

Some examples:

- For a square tube made of S355 with a diameter of 100x100x8 mm, which is bent through 90° with an internal radius of 200 mm, the deformation of the bent tube cross-section is 105.8×99.4 mm.

- The ovalization of a stainless steel round tube bent through 90° with a diameter of Ø50×2 mm and an average bending radius of 105 mm is approximately 3% (Ømax=50.1/Ømin=48.5).

Deformation of the pipe thickness

The deformation of the pipe cross-section due to bending not only leads to a change in the diameter, but also to a change in the pipe thickness. The deformation of the thickness of the bent pipe is immediately visible when the pipe is cut.

Due to the deformation, the following two phenomena occur:

- Thickness compression: The thickness of the inner wall of the bent pipe increases due to compression.

- Thickness thinning: The thickness of the outer wall of the bent pipe tends to decrease due to the thinning.

To achieve good pipe bending quality, it is important to find the right balance between compression and thickness thinning. This balance is achieved by considering several factors, including

- Pipe cross-section

- Pipe thickness

- Degree of bending

- Bending radius

- metal

- Pressure device for the inside and to eliminate wrinkles

- Booster (thrust force of some tube bending machines) to reduce the thinning of the outside during bending

Is it possible to control and limit pipe deformation?

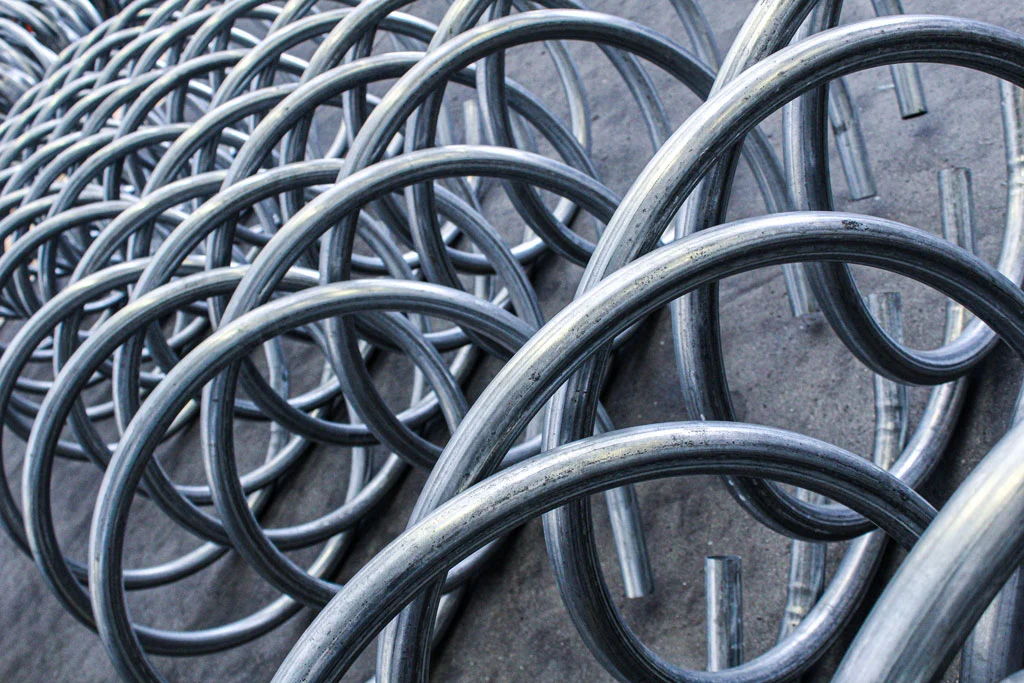

As the deformation of the pipe cross-section is always caused by bending and roll bending the pipe, there is a way of limiting the deformation. How is this achieved? By using special tools that enable precise bending of the pipe:

- Fixed mandrels

- Swivel mandrels

- Counter slide

For square/rectangular pipes, on the other hand, we use a limiting piston on the die: this is a device that limits the deformation of the top of the bent piece of pipe and limits the deformation of the vertical side of the square pipe by exerting a certain pressure.

Conclusions

When bending and rolling tubes, there is always a deformation of the profile in the bending area.

One of the most important quality aspects of professional tube bending at Tecnocurve is to take all necessary measures to control and limit the deformation of the tube diameter and thickness as a result of the processing.

Thanks to our machinery and the large number of fixtures available for most tube profiles, we are able to help companies find the best solutions for their needs.