Deformation of the bent pipe cross-section

The bending of metal pipes, profiles and tubular products is a cold forming process in which the straight pipe is bent. This article explains the

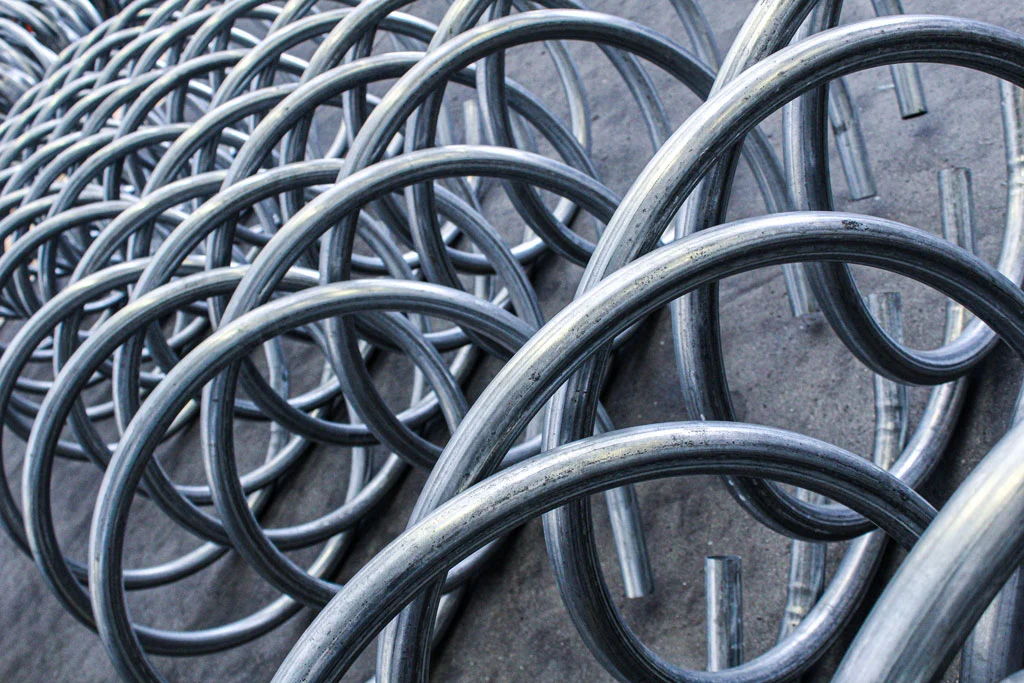

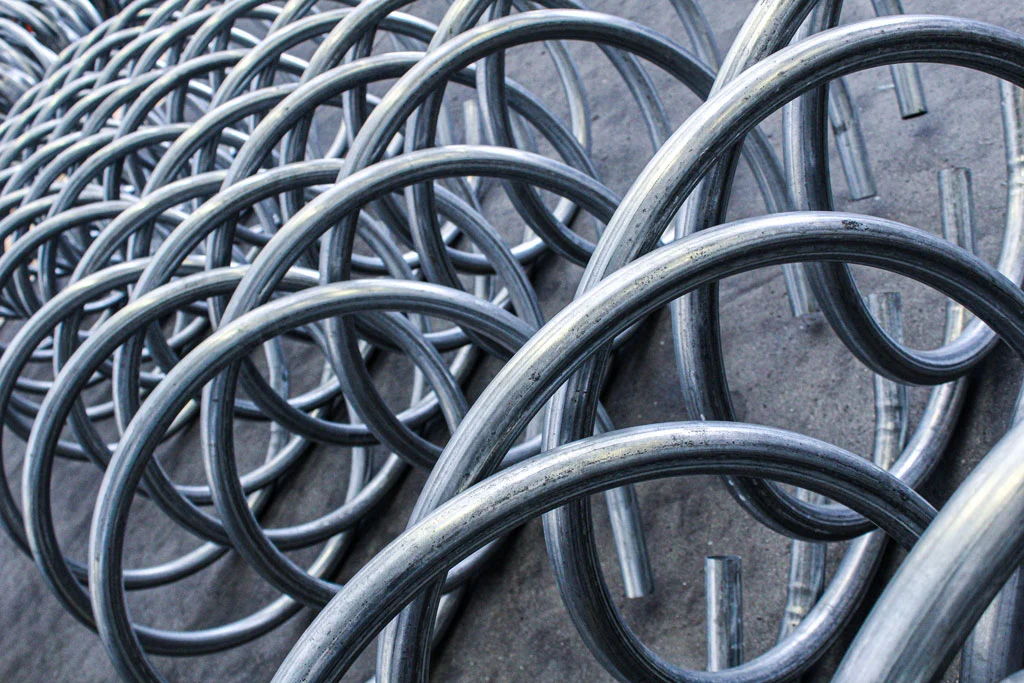

In this section you will find the articles of our blog on the bending of metal tubes, tubular elements and section bars. Discover the advantages of cold bending, the methods and processes used for bending, how to define the feasibility of the bend for a tube and the importance of the bend radius and metal alloy. We hope you enjoy reading them!

Do you have any questions? Fill out the form or send us an email. We will answer promptly.

The bending of metal pipes, profiles and tubular products is a cold forming process in which the straight pipe is bent. This article explains the

According to a simple definition, the bending radius is the distance between the centre of a circle and its circumference. In mandrel bending, the bending

Read this article to find out more about tubing bending for agricultural machinery, its function and the importance. Indice dei contenuti What is agricultural machinery?

The precision required for tube bending and other types of tube processing, such as laser tube cutting, tube rolling and tube welding, means that the

Bending or rolling or roll bending aluminium tubes (aluminium pipe bending) and aluminium sections (aluminium profile bending) is achieved by cold forming or cold bending.

There are key differences between these two bending methods for aluminium tubing and sections.

This article talks about the techniques for bending and rolling a steel or stainless steel tube.

The bend radius is a fundamental parameter for the bend feasibility analysis of a tube: it is essential because it is the value that defines the coefficient which will indicate the degree of difficulty of cold bending.

Welding, laser cutting, bending and roll bending are perhaps the most important processes carried out on metal tubes.

Cold bending for the production of bent parts used in forestry machines and in the equipment typical of the forestry sector.

In this article we deal with the subject of tube bending as an alternative to welding.

We are at your disposal.

Please do not hesitate to contact us for information, clarifications or inquiries about our processes on metal tubes.

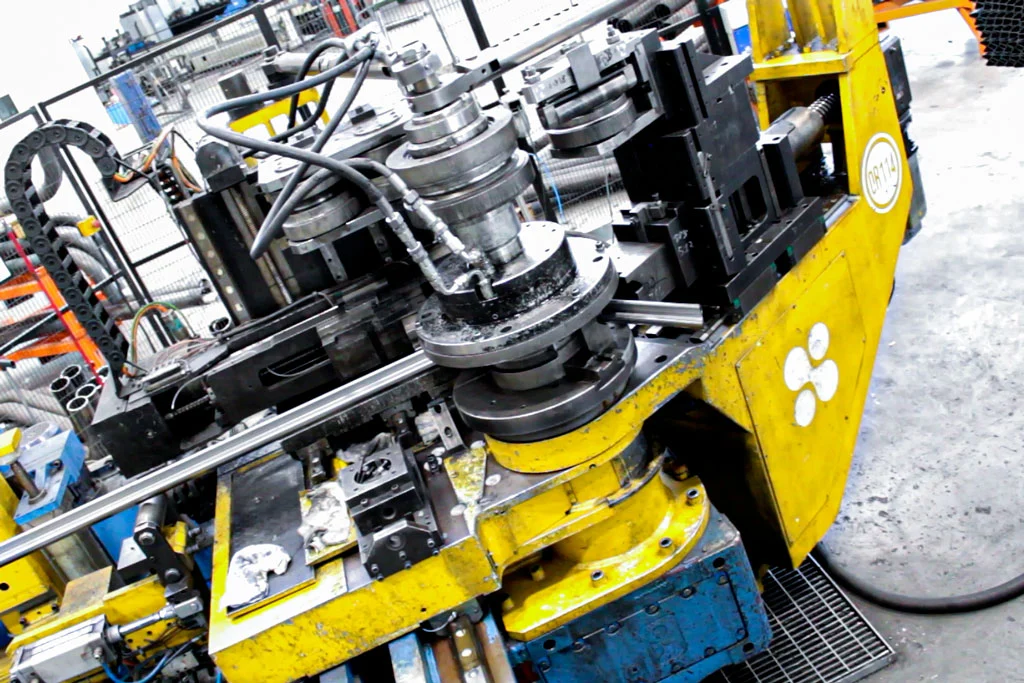

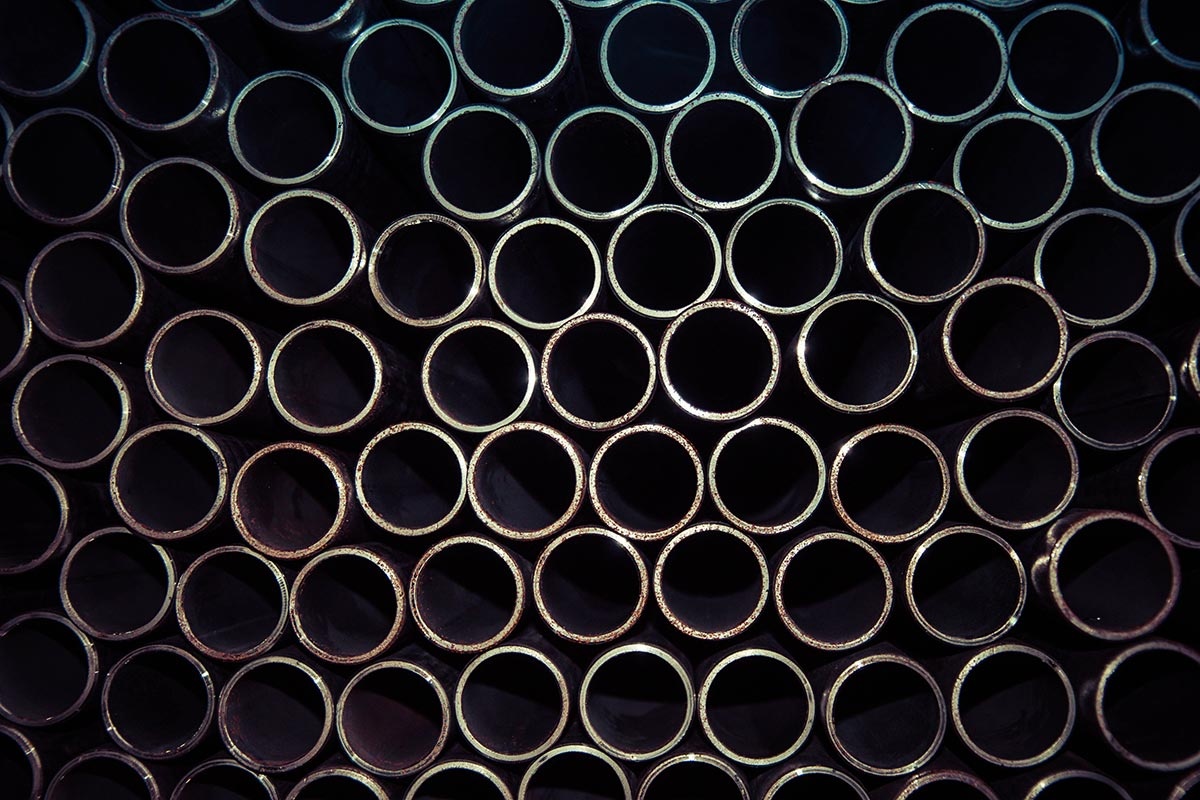

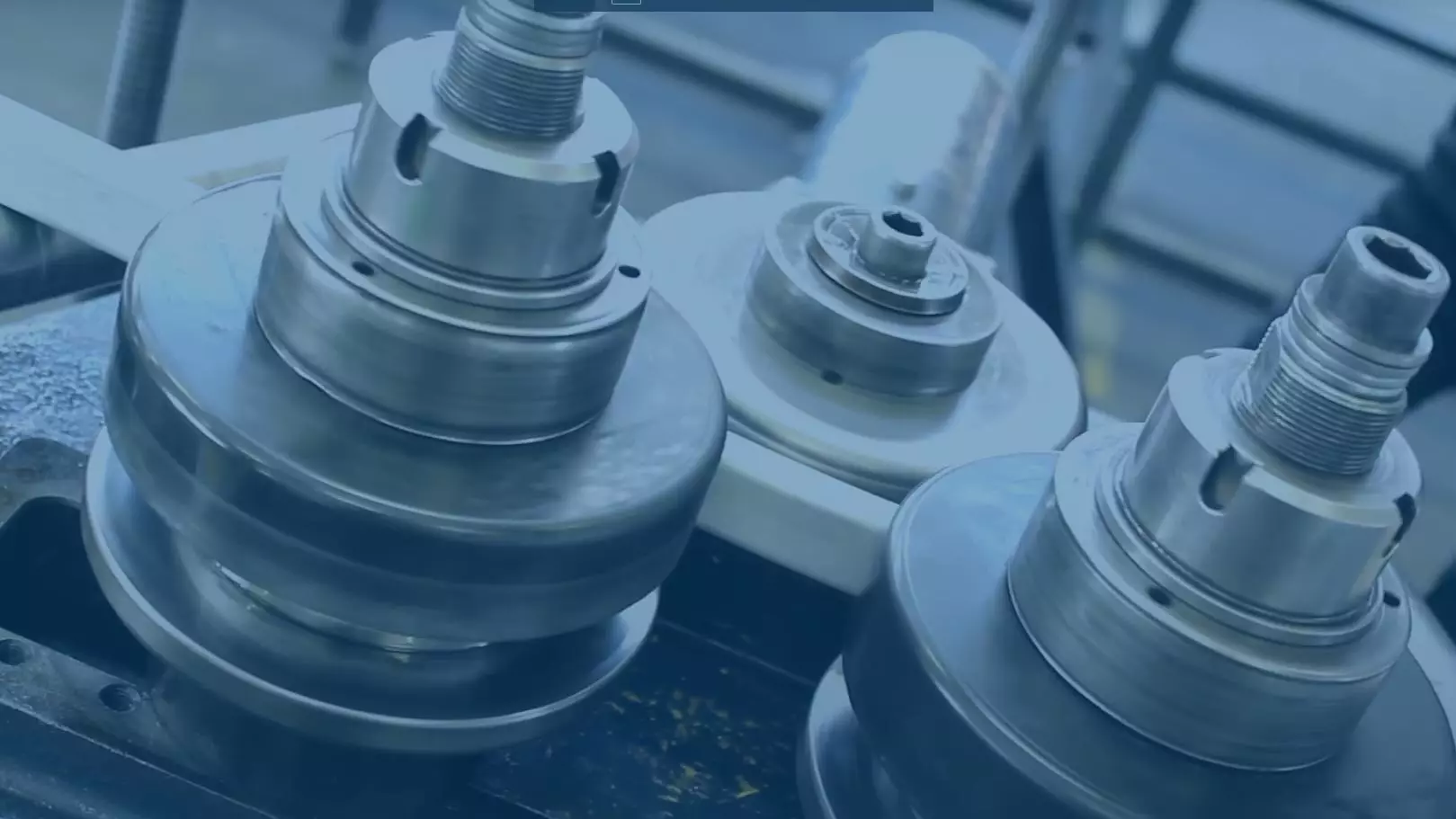

Since 1991, we have been specialized in the cold bending of tubes, tubular elements and special metal section bars.

The service offered to the clients and a high quality fleet of modern, technological machines, make Tecnocurve the ideal partner for bending and roll bending tubes in steel, stainless steel and aluminum.

Call us at +39 045 69 69 200 or fill out the form to submit your request with all the necessary information for our analysis:

© 2015-2025 – All rights reserved.

VAT no. and listing number in the Register of Companies of Verona: 04122440235

Share capital fully paid in: € 100,000.00 EAR number: VR-393959

This site uses only technical cookies, as indicated in the Cookie Policy.

Credits: 045WEB

© 2015-2025 – All rights reserved.

VAT no. and listing number in the Register of Companies of Verona: 04122440235

Share capital fully paid in: € 100,000.00 EAR number: VR-393959

Privacy Policy – Terms and conditions of use

This site uses only technical cookies, as indicated in the Cookie Policy.

Credits: 045WEB

© 2015-2025 – All rights reserved. – VAT no. and listing number in the Register of Companies of Verona: 04122440235 – Share capital fully paid in: € 100,000.00 EAR number: VR-393959

Privacy Policy – Terms and conditions of use – This site uses only technical cookies, as indicated in the Cookie Policy.

Credits: 045WEB